Precision measurement of ferromagnetic steel tubes

The CIRCOSON WT sensor system works on the basis of the so-called EMAT (Electro Magnetic Acoustic Transducer) method. This method electromagnetically creates and receives ultrasound waves. The EMAT method facilitates ultra precision wall thickness measurements of ferromagnetic seamless steel tubes in accordance with international standards. The data is transferred directly to the CIRCOSON WT test and evaluation equipment where it is processed and analyzed. The system reaches a wall thickness measurement accuracy of approx. ± 50 μm and maximum throughput of up to 3.2 m/s during continuous testing.

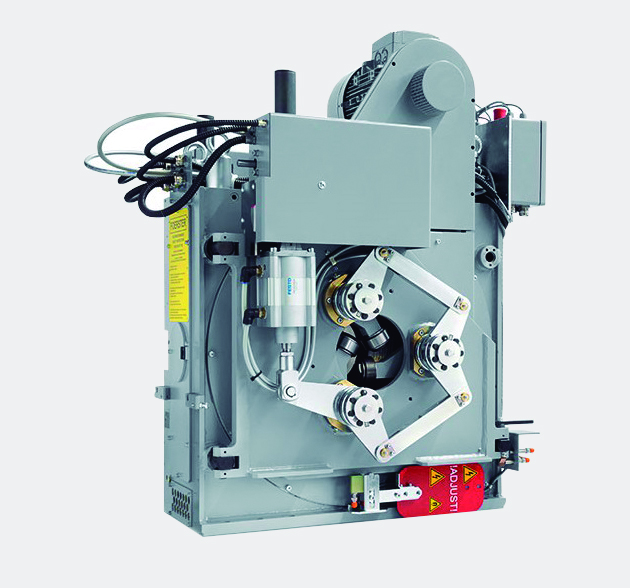

The CIRCOSON WT system is often used together with the ROTOMAT and TRANSOMAT system. The latter perform additional material testing for longitudinal and transverse defects. As a complete system provider, FOERSTER develops tailored testing lines that perfectly meet your requirements.

The available sensor systems cover a material diameter range from approx. 10 to 180 mm. FOERSTER’s long-standing experience in this field ensures high operating reliability. The modular design of the test electronics is also ideally suited to meet future demand for ever increasing defect detection sensitivity.